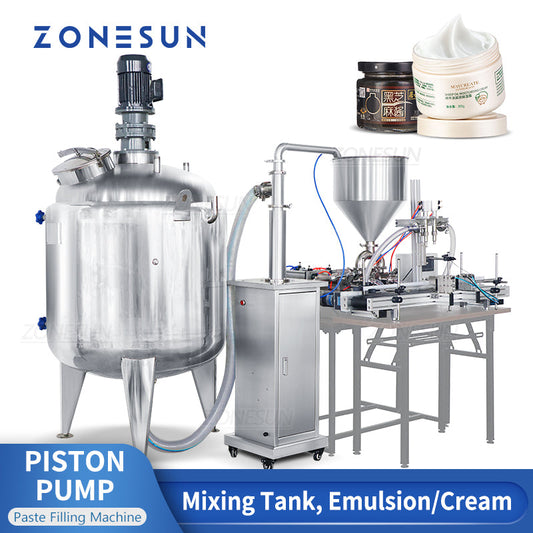

High Viscosity Filling Solutions

ZONESUN is your one-stop solution provider for paste and viscous product filling. We specialize in delivering advanced filling machines designed to handle a wide range of viscous and semi-solid products, including honey, ketchup, creams, gels, sauces, pastes, and more.

Our paste filling machines are engineered for stable, precise, and efficient filling, ensuring consistent product quality every time. Whether you need tabletop semi-automatic machines for small-scale production or high-output fully automatic systems for large-scale industrial lines, ZONESUN offers solutions tailored to your production needs.

-

ZONESUN ZS-YT6T-6PX 6 Nozzles Servo Motor Paste Filling Machine With Feeding Pump

Harga reguler Dari $7,499.00 USDHarga reguler -

ZONESUN ZS-DTPT2 Automatic Pneumatic Piston Pump Paste Filling Machine

Harga reguler $5,339.00 USDHarga reguler -

ZONESUN ZS-DTGT900U Automatic Rotor Pump Paste Filling Machine With Mixer Hopper

Harga reguler $2,999.00 USDHarga reguler -

ZONESUN ZS-DTGT2 Automatic 2 Lifting Nozzles Pneumatic Piston Pump Paste Filling Machine

Harga reguler Dari $1,689.99 USDHarga reguler -

ZONESUN ZS-GT2P 2 Nozzles Fully Pneumatic Sauce Paste Filling Machine

Harga reguler Dari $989.00 USDHarga reguler -

ZONESUN ZS-RXB1 Dual-use Flexible Impeller Pump Particulate Liquid Paste Filling Machine

Harga reguler Dari $1,089.00 USDHarga reguler -

ZONESUN ZS-GTRP2 Semi-automatic 2 Nozzles Rotor Pump Paste Filling Machine

Harga reguler $4,099.00 USDHarga reguler

Konten yang dapat ditutup

What is a Paste Filling Machine?

A paste filling machine is an automated device specifically designed for filling high-viscosity liquids or semi-solid materials. It is widely used in the food, cosmetics, chemical, and daily chemical industries for products such as honey, jam, chocolate paste, creams, lotions, and adhesives.

Working Principle

Paste filling machines typically use piston pumps, rotor pumps, or gear pumps, which apply mechanical pressure to accurately inject high-viscosity materials into containers. Compared to ordinary liquid filling machines, they can handle thick, slow-flowing materials, ensuring uniform filling without dripping. Some models also support multi-head filling for higher production efficiency.

Key Functions and Advantages

-

High-Precision Filling

Each filling volume can be adjusted to ensure consistent product specifications and minimize waste. -

Suitable for Various Viscosities

Stable filling is possible for both thick sauces and semi-solid pastes. -

Improved Production Efficiency

Automated operation saves labor and supports continuous production, greatly increasing output. -

Easy Operation and Cleaning

Compact structure, easy to disassemble, ideal for frequent material changes and cleaning. -

Reduced Production Costs

Precise filling control reduces material waste and labor costs.

Applications and Industries

- Food Industry: sauces, jams, honey, chocolate paste, condiments

- Cosmetics Industry: creams, lotions, shampoos, skincare pastes

- Chemical Industry: adhesives, lubricants, colloidal products

- Others: medicinal pastes, specialty viscous liquids

Choosing a Paste Filling Machine

When selecting a paste filling machine, consider material viscosity, production volume, container type, and automation level. Advanced models may feature touch-screen control, automatic calibration, and multi-head synchronous filling to meet diverse production requirements.

Professional Paste Filling Machines for Low to High Viscosity Materials

ZONESUN paste filling machines deliver high-precision and efficient solutions for filling a wide range of materials, from low-viscosity liquids to high-viscosity creams, gels, and sauces. Featuring gear, piston, servo, and rotary pumps, our viscous filling equipment ensures accurate dosing, consistent output, and easy cleaning, making it ideal for food, cosmetics, pharmaceutical, and chemical industries.

At ZONESUN, we understand that precise and efficient paste filling is critical for industries ranging from food and cosmetics to pharmaceuticals and chemicals. That’s why our paste filling machines are designed with multiple pump types — gear pumps, piston pumps, servo pumps, and rotary pumps — to handle everything from low-viscosity liquids to high-viscosity pastes.

Our versatile viscous filling machines ensure accuracy, reliability, and consistency, providing the ideal solution for any production line. With a modular design, each machine can be customized to match your product’s viscosity, production speed, and packaging type.

Multi-Pump Options for Different Viscosity Products

1. Gear Pump Paste Filling Machine

- Suitable for: Low to medium viscosity products (e.g., serums, light lotions, liquid chemicals)

-

Features:

- Continuous and stable flow

- Compact structure, easy to clean and maintain

- Gentle pumping that preserves product integrity

- Typical Applications: Cosmetic serums, low-viscosity cleaning liquids, insecticides

✅ Advantages: Cost-effective, precise, ideal for high-speed continuous production

2. Piston Pump Viscous Filling Machine

- Suitable for: Medium to high viscosity products (e.g., creams, gels, pastes)

-

Features:

- High output pressure, resistant to clogging

- Accurate per-stroke volume for micro-filling

- Can handle particles or fibrous material

- Typical Applications: Skincare creams, oral gels, food sauces

✅ Advantages: Excellent control over high-viscosity products, minimal dosing error

3. Servo Pump High Viscosity Filler

- Suitable for: Full viscosity range (low to ultra-high)

-

Features:

- Servo motor-driven pump allows real-time speed and stroke adjustment

- Supports complex filling curves and variable speeds

- High-precision dosing for advanced packaging requirements

- Typical Applications: Premium sauces, specialty chemicals, medical gels

✅ Advantages: Maximum filling accuracy with scalable production options

4. Rotary Pump Paste Filling Machine

- Suitable for: Medium to high viscosity products, especially shear-sensitive or particle-containing materials

-

Features:

- Smooth, low-shear pumping action

- Handles semi-solid pastes and chunky products

- Stable output even for products with varying viscosity

- Typical Applications: Nut butters, jams, tomato paste, cosmetic gels, adhesive pastes

✅ Advantages: Excellent for delicate or chunky materials, consistent volume per cycle

Key Advantages of Paste Filling Equipment

- Flexible & Modular Design: Choose the right pump type and number of filling heads based on product viscosity and production line speed. Compatible with round bottles, flat bottles, tubes, jars, and pouches.

- High Efficiency & Consistency: Automated filling systems with precise volume control guarantee uniform filling and minimize waste.

- Easy Cleaning & Maintenance: Detachable pump bodies and hygienic flow paths support quick CIP/SIP cleaning processes, perfect for food and pharmaceutical applications.

- Smart Control & User-Friendly Operation: PLC touch-screen interface for easy adjustment of filling parameters, speed, and alarm functions. Servo models support remote monitoring and data logging.

Expanded Industry Applications

Our paste filling machines and viscous filling equipment serve a wide range of industries and applications:

| Industry | Typical Products |

|---|---|

| Food & Beverage | Sauces, mayonnaise, condiments, jams, nut butters, pastes, chocolate spreads, tomato paste, honey |

| Cosmetics & Personal Care | Creams, lotions, facial cleansers, hair gels, body gels, ointments |

| Pharmaceutical & Healthcare | Medical gels, ointments, oral gels, nutraceutical pastes |

| Chemical & Industrial | Lubricants, adhesives, sealants, polymer pastes, epoxy, silicone pastes |

| Specialty & Gourmet Foods | High-viscosity sauces, marmalades, premium condiments, specialty nut butters |

Why Choose Paste Filling Machines?

ZonesunPro provides industry-leading paste filling equipment and expertise for accurate viscous filling. Our multi-pump technology ensures precise dosing for low to high viscosity products, making our viscous filling machines perfect for startups and large-scale production alike.

- Custom filling solutions for your product

- Full pre-sales and after-sales support

- High-value, reliable equipment

📩 Contact us today to get a quote or schedule a demo for your high-viscosity filler!

Paste Filling Solutions for Food, Cosmetic, and Chemical Industries

Different industries require specialized filling equipment. Zonesun focuses on the design and manufacture of paste filling machines, providing reliable, high-efficiency solutions for the food, cosmetic, and chemical sectors. Whether it’s sauces, creams, lotions, or chemical gels, Zonesun machines ensure accurate, consistent filling and improve production efficiency.

Food Industry Applications

Food production demands hygiene and precise filling. Zonesun paste filling machines are ideal for automatically filling sauces, ketchup, peanut butter, chocolate spreads, and other food pastes, ensuring both high output and consistent product quality.

Cosmetic Industry Applications

The cosmetic industry requires filling equipment that is precise, clean, and visually appealing. Zonesun machines are suitable for creams, hand lotions, facial creams, gels, and other cosmetic pastes, helping cosmetic manufacturers achieve automated packaging and efficient production.

Chemical Industry Applications

Chemical paste or gel products often have high viscosity or corrosive properties. Zonesun paste filling machines are made of corrosion-resistant materials, allowing safe, accurate filling of chemical products while reducing production risks and increasing efficiency.

About Zonesun – Trusted Manufacturer and Supplier

Zonesun is a professional paste filling machine manufacturer and supplier, providing high-quality, customized filling solutions for global food, cosmetic, and chemical industries. We focus on precision, durability, and ease of operation, helping companies upgrade to automated production..