ZONESUN ZS-FAL180D6 4 Nozzles Magnetic Pump Liquid Filling Cap Screwing Round Bottle Labeling Production Line

ZONESUN ZS-FAL180D6 4 Nozzles Magnetic Pump Liquid Filling Cap Screwing Round Bottle Labeling Production Line

Couldn't load pickup availability

Pre-sale Support

Pre-sale Support

Chinese Company: Guangdong Shanghang Technology Co., Ltd.

Headquarters Address: No.8,Lane1 East Dianbian Road,Nanyue,Shang An, Jinsha, Danzao Town, NanHai District , FoShan City , GuangDong Province , China.

Postcode: 528223

ZONESUNPRO.COM is the official website of the ZONESUN brand. To protect your rights, please verify the website address before placing an order to avoid visiting counterfeit or unauthorized websites.

Trust & Guarantee

Trust & Guarantee

Payment & Delivery Assurance

1. Secure Payment

1. Secure Payment

We accept payments via PayPal and major credit cards through official third-party payment platforms. Buyer protection applies in accordance with the policies of the respective payment service providers.

2. Pre-Shipment Verification

Before shipment, a real machine operation and testing video will be provided to demonstrate the actual working condition and key performance of the equipment.

3. Post-Delivery Support

After delivery, installation and commissioning guidance videos will be provided to support proper setup and operation. Technical assistance is available when required.

4. Clear Commitment

If the delivered machine does not meet the agreed technical specifications or materially differs from what was demonstrated in the pre-shipment video, appropriate solutions will be provided based on the specific situation, including technical adjustment or other reasonable handling measures.

About ZONESUN

We are Zonesun, dedicated to building long-term partnerships based on transparency, verifiability, and accountability. We specialize in filling machines, capping machines, labeling machines, and complete automated production line solutions, along with a full range of supporting packaging equipment. For more information, please visit our official website: www.zonesunpro.com

Official Website: https://www.zonesunpro.com

Customer Service Email: info@zonesunpro.com (Kevin Peng)

Whatsapp/Phone/Tell: +86 189 2864 2633

Company Address: No. 8, Lane 1, East Dianbian Road, Nanyue Village, Shangan, Jinsha Town, Nanhai District, Foshan, Guangdong, China

DESCRIPTION

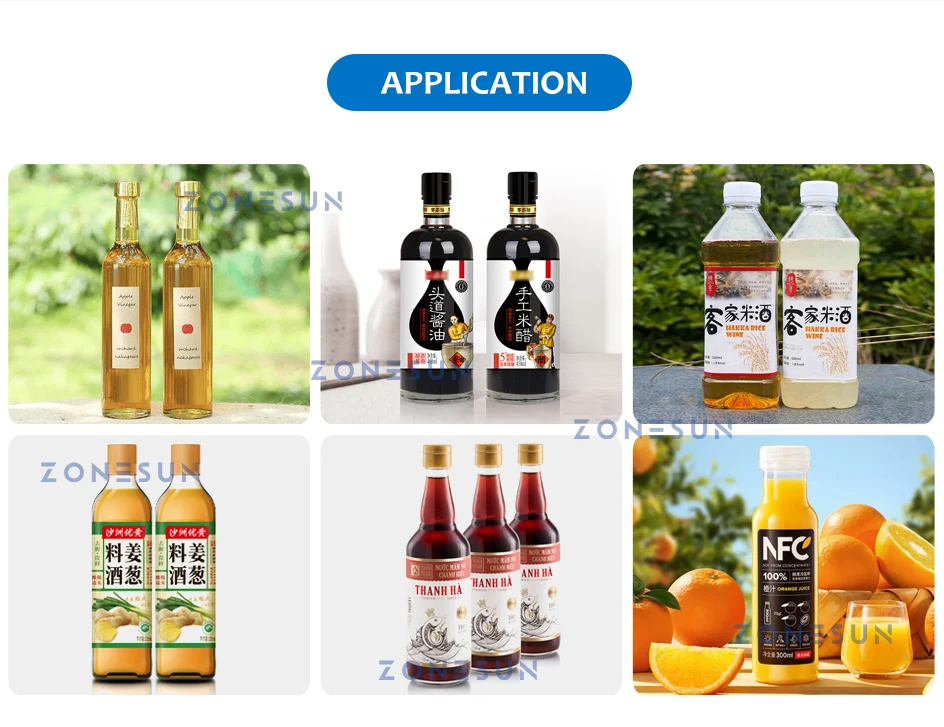

This line consistsofan unscrambler, a filler, a cap feeder, a capper, a label applicator, and a collector. It is widely used in the food, daily chemical, and cosmetics industries. It greatly saves working space.

PARAMETER

|

UNSCRAMBLER |

|

|

Model |

ZS-LP600Z |

|

Turntable Diameter |

600mm |

|

Suitable Bottle Diameter |

30-80mm |

|

Suitable Bottle Height |

≤2500mm |

|

Working Speed |

40-60 bottles/min(depends on bottle |

|

Motor Power |

40W |

|

Power Supply |

220V/50-60HZ |

|

Net Weight |

About 27.5kg |

|

Package Size |

About 700*740*960mm |

|

Gross Weight |

About 60kg |

|

FILLING MACHINE |

|

|

Machine Model |

ZS-DTMP4AL |

|

Power Supply |

110/220V 50-60HZ 300W |

|

Maximum Flow Velocity |

6000ml/min (Each nozzle and base on water) |

|

Working Speed |

20-30 bottles/min |

|

Air Pressure |

0.3-0.4MPa |

|

Filling Accuracy |

≤±1% (For water) |

|

Diameter of Filling Nozzle |

6/8mm |

|

Delay Range |

0.01-999.9s |

|

Count Range |

1-99999 Times |

|

Filling Volume |

3-1000ml |

|

Size of Air Compressor Connector |

OD8mm |

|

Machine Size |

About 1100*580*1110mm |

|

Package Size |

About 1140*650*840mm |

|

Net Weight/Gross Weight |

About 74kg/90kg |

|

VIBRATORY BOWL |

|

|

Machine Power |

110/220V 50-60HZ |

|

Material |

Stainless Steel |

|

Suitable Caps Diameter |

Customizable |

|

Working Speed |

|

|

Machine Size |

|

|

CAPPING MACHINE |

|

|

Model |

ZS-XG1870V |

|

Bottle Height |

60-270mm |

|

Bottle Caps Diameter |

18-70mm |

|

Working Speed |

20-40 bottles/minute(depending on bottle and |

|

Working Voltage |

AC220V/110V 50-60HZ |

|

Working Pressure |

0.4-0.6 MPa |

|

Machine Size |

About 2130*1090*1040mm |

|

Package Size |

About 1160*610*1140mm |

|

Package Weight |

About 97.5kg |

|

Conveyor Length |

1117mm |

|

Size of Air Compressor Connector |

OD 8mm |

|

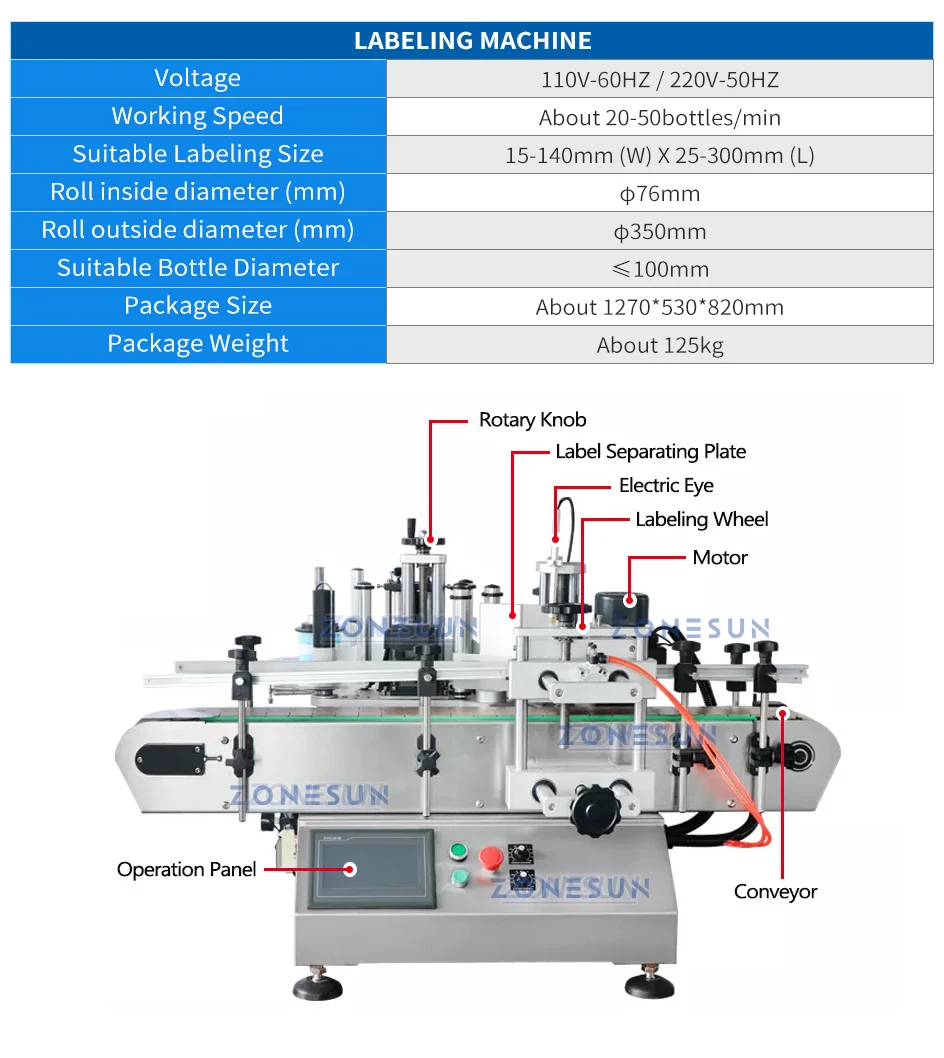

LABELING MACHINE |

|

|

Voltage |

110V-60HZ / 220V-50HZ |

|

Working Speed |

About 20-50bottles/min |

|

Suitable Labeling Size |

15-140mm (W) X 25-300mm (L) |

|

Roll inside diameter (mm) |

φ76mm |

|

Roll outside diameter (mm) |

φ350mm |

|

Suitable Bottle Diameter |

≤100mm |

|

Package Size |

About 1270*530*820mm |

|

Package Weight |

About 125kg |

|

TURUTABLE |

|

|

Model |

ZS-SP600Z |

|

Turntable Diameter |

600mm |

|

Suitable Bottle Diameter |

30-80mm |

|

Suitable Bottle Height |

≤2500mm |

|

Working Speed |

40-60 bottles/min (Depends on bottle size) |

|

Motor Power |

40W |

|

Power Supply |

220V/50-60HZ |

|

Package Size |

About 700*740*740mm |

|

Net Weight/Gross Weight |

About 32.5kg/50kg |

PRODUCT DETAILS

UNSCRAMBLING

600mm in diameter, adjustable speed

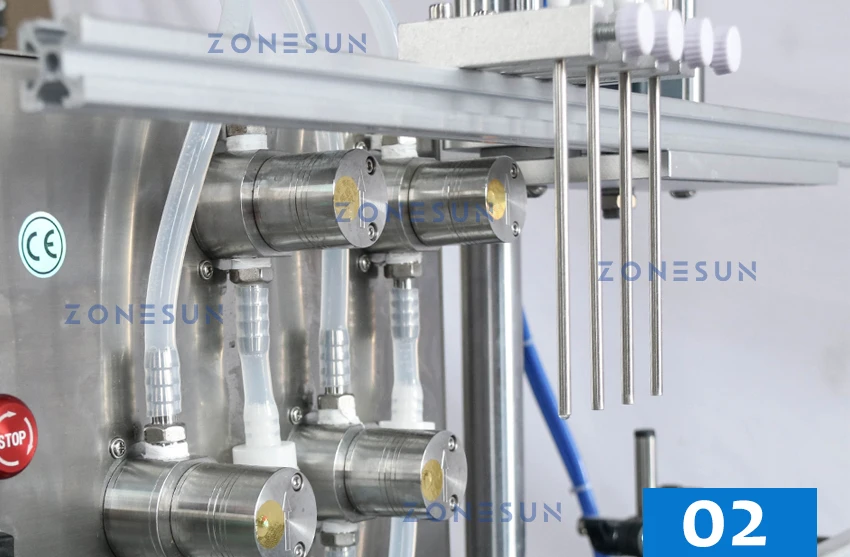

FILLING

Diving Nozzles, Magnetic Pumps, 316L stainless steel

CAPPING

4 rubber wheels for various screw caps.

1tapping bar for fixing caps.

Powerful dual motors.

LABELING

Round bottles, no bubbles, available to be assembled with a date printer

Share