ZONESUN ZS-FAL180X8 4 Heads Piston Pump Liquid Filling Capping Square Bottle Double Sizes Labeling Machine

ZONESUN ZS-FAL180X8 4 Heads Piston Pump Liquid Filling Capping Square Bottle Double Sizes Labeling Machine

픽업 사용 가능 여부를 로드할 수 없습니다.

Pre-sale Support

Pre-sale Support

Chinese Company: Guangdong Shanghang Technology Co., Ltd.

Headquarters Address: No.8,Lane1 East Dianbian Road,Nanyue,Shang An, Jinsha, Danzao Town, NanHai District , FoShan City , GuangDong Province , China.

Postcode: 528223

ZONESUNPRO.COM is the official website of the ZONESUN brand. To protect your rights, please verify the website address before placing an order to avoid visiting counterfeit or unauthorized websites.

About ZONESUN

About ZONESUN

Guangdong Shanghang Technology Co., Ltd.: Your Reliable Partner in Packaging Machinery Solutions

Founded in 2003, Guangdong Shanghang Technology Co., Ltd. has established itself as a leading high-tech enterprise specializing in the research, development, manufacturing, and sales of packaging machinery equipment. With headquarters located in the vibrant Nanhai District of Foshan, we boast a dedicated team of senior technical personnel and management talents, committed to delivering high-quality, high-performance packaging machinery equipment, and comprehensive solutions to our valued customers.

Driven by our core values of "quality, service, innovation, and win-win," Guangdong Shanghang Technology Co., Ltd. is dedicated to achieving excellence in the packaging machinery industry. We are committed to continuously developing new products and enhancing their quality, while also improving our after-sales service levels. This unwavering commitment has earned us the trust and praise of customers both domestically and internationally, solidifying our position as a trusted and preferred partner in the industry.

Driven by our core values of "quality, service, innovation, and win-win," Guangdong Shanghang Technology Co., Ltd. is dedicated to achieving excellence in the packaging machinery industry. We are committed to continuously developing new products and enhancing their quality, while also improving our after-sales service levels. This unwavering commitment has earned us the trust and praise of customers both domestically and internationally, solidifying our position as a trusted and preferred partner in the industry.

To further enhance our customer experience, we have established multiple overseas warehouses located in various countries around the world. These strategically located warehouses enable us to ensure timely delivery of our products and significantly reduce shipping costs for our valued customers. With our efficient distribution network, we can promptly respond to customer demands and provide seamless support wherever they are.

At our company, we believe in the power of customization. We understand that every business has unique packaging needs, and we are dedicated to providing customized packaging machinery solutions to meet those needs. With a team of highly skilled engineers and technicians, we work closely with our customers to design and develop tailored solutions that align with their specific requirements.

At our company, we believe in the power of customization. We understand that every business has unique packaging needs, and we are dedicated to providing customized packaging machinery solutions to meet those needs. With a team of highly skilled engineers and technicians, we work closely with our customers to design and develop tailored solutions that align with their specific requirements.

We take great pride in our commitment to innovation and the development of core technologies. As a result, our company holds independent intellectual property rights for our cutting-edge machinery. Many of our products have been recognized and awarded national patents, showcasing the uniqueness and originality of our solutions.To ensure the highest standards of quality and reliability, our products undergo rigorous testing and evaluation. We are proud to have obtained certifications such as CE and ISO9001, demonstrating our dedication to meeting international quality standards.

ZONESUN Official Website Statement

zonesunpro.com is the officially designated website of the ZONESUN brand. Welcome to the ZONESUN Packaging Machinery Store! To protect your interests, please verify the website address before placing any orders and avoid visiting counterfeit or unauthorized sites.

✅ Ensure the website begins with https:// and displays the padlock icon in your browser to confirm a secure connection.

✅ The domain must be exactly zonesunpro.com, with no prefixes or suffixes.

✅ Contact ZONESUN’s official customer service team, who can assist you online in verifying the website or arranging an online factory visit.

ZONESUN is committed to providing genuine, reliable products and services. Thank you for your continued trust and support.

Contact Us

Official Website: https://www.zonesunpro.com

Customer Service Email: info@zonesunpro.com

Whatsapp/Phone/Tell: +86 189 2864 2633

Company Address: No. 8, Lane 1, East Dianbian Road, Nanyue Village, Shangan, Jinsha Town, Nanhai District, Foshan, Guangdong, China

ZONESUN reserves the right to update this statement at any time.

DESCRIPTION

This automatic production line consists of a filling machine, a capping machine, and a labeling machine, which greatly improves production efficiency and saves labor. It applies to daily chemical products, skin care products, liquid healthcare products, etc.

PARAMETER

FILLING MACHINE |

||

|

Model |

ZS-YT4T-4D |

|

|

Voltage |

110/220V 50-60HZ 600W |

|

|

Filling Range |

5-100ml/10-300ml/50-500ml/100-1000ml/500-3000ml/1000-5000ml |

|

|

Working Speed |

About 20-35bottles/min(depend on bottle size and liquid) |

|

|

Filling Accuracy |

≤±1% |

|

|

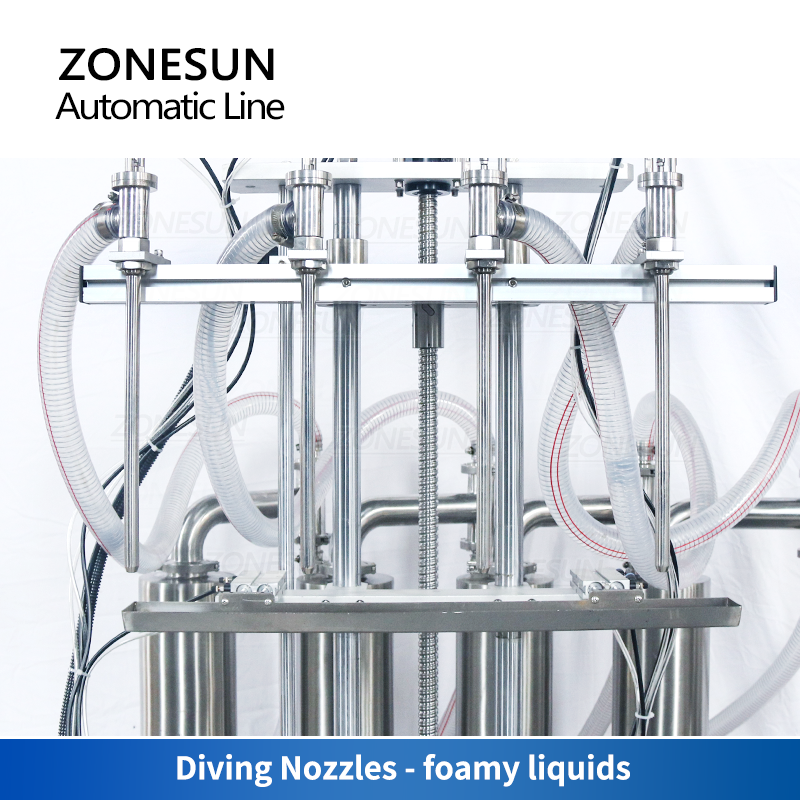

Filling Heads Type |

Diving Filling Heads(Suitable for foamy liquid) |

|

|

Air Pressure |

0.5-0.7MPa |

|

|

Size Of Air Compressor Connector |

OD 10mm |

|

|

Conveyor Length |

2050mm(standard) |

|

|

Conveyor Material |

Plastic(standard)/Stainless Steel(custom version) |

|

|

Machine Size |

About 2900*1285*2200mm(1000-5000ML) |

|

|

Package Size |

About 1700*1390*2320mm(1000-5000ML) |

|

|

Net Weight/Gross Weight |

About 461kg/480kg(1000-5000ML) |

|

CAPPING MACHINE |

||

|

Machine Model |

ZS-XG16F |

|

|

Voltage |

AC220V/110V 50- 60HZ |

|

|

Bottle Height |

30-300mm |

|

|

Cap Diameter |

18-70mm |

|

|

Bottle Diameter |

20-160mm |

|

|

Working Speed |

20-60 bottles/minute (depending on bottle and cap size) |

|

|

Working Pressure |

0.4-0.6MPa |

|

|

Machine Size |

About 1930*650*1800mm |

|

|

Machine Weight |

About 141kg |

|

|

Package Size |

About 1970*360*1840mm |

|

|

Gross Weight |

About 284kg |

|

LABELING MACHINE |

||

|

Machine Model |

ZS-TB300V |

|

|

Voltage |

110V-60HZ/220V-50HZ |

|

|

Power |

3100W |

|

|

Working Speed |

30-100 bottles/min |

|

|

Labeling Accuracy |

±0.5mm |

|

|

Suitable Labeling Size |

≤200mm(W)(Can be customized) |

|

|

Roll Inside Diameter(mm) |

Φ75mm |

|

|

Roll OutsideDiameter(mm) |

Φ250mm |

|

|

Suitable Bottle Diameter |

φ≤100mm H≤350mm |

|

|

Conveyor Size |

About 1800*100mm |

|

|

Machine Size |

About 1800*1250*1450mm(L*H*W) |

|

|

Package Size |

About 1850*1135*1560mm(L*H*W) |

|

|

Net Weight/Gross Weight |

About 213kg/268kg |

|

PRODUCT DETAILS

DIVING NOZZLES

The filling heads will move down and up during filling, preventing liquid from splashing out. The number of filling heads can be customized as needed.

CAPPING HEAD

It can be customized according to the bottle cap’s diameter and height. The height of the capping head can be adjusted according to the bottles’ height.

ROTARY HANDLES

They’re designed for adjusting the position of label structure, ensuring that the labels can be sticked accurately.

BOTTLE GUIDING STRUCTURE

It is designed for clamping bottles during capping, preventing them from falling down. The width of it can be adjusted according to the bottles’ size.

PHOTOELECTRIC EYE

It is used for detecting bottles and controlling the machine to work automatically. Intelligent and efficient. The sensitivity of it is adjustable.

Share