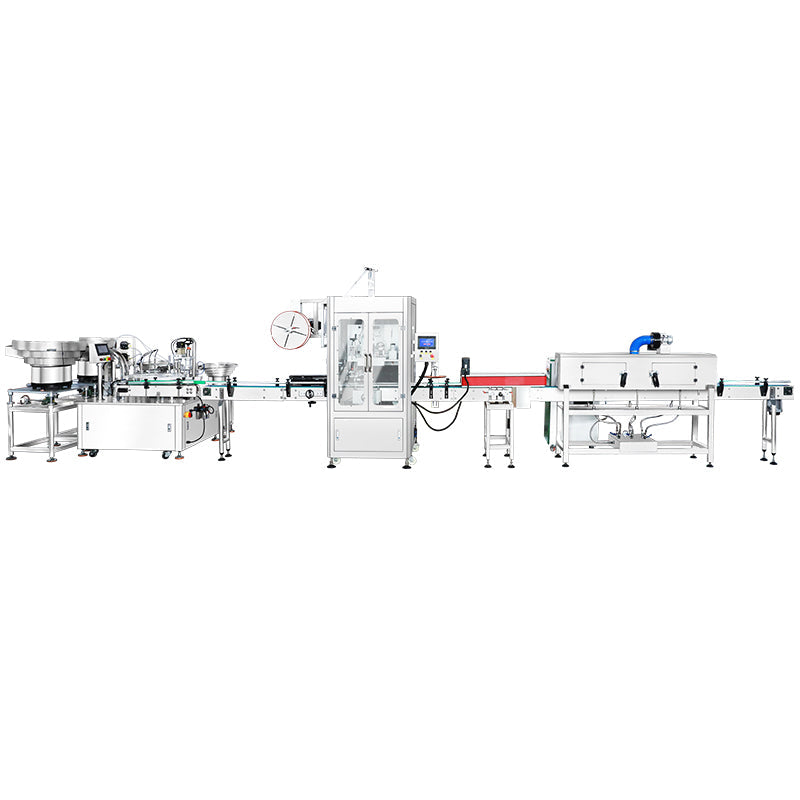

ZONESUN ZS-FAL180G9 Automatic Eye Drop Cam System Filling Capping Shrink Sleeve Labeling Production Line Irregular Bottle Biological Extract Liquid Peristaltic Pump Filling Machine

ZONESUN ZS-FAL180G9 Automatic Eye Drop Cam System Filling Capping Shrink Sleeve Labeling Production Line Irregular Bottle Biological Extract Liquid Peristaltic Pump Filling Machine

Couldn't load pickup availability

Pre-sale Support

Pre-sale Support

Chinese Company: Guangdong Shanghang Technology Co., Ltd.

Headquarters Address: No.8,Lane1 East Dianbian Road,Nanyue,Shang An, Jinsha, Danzao Town, NanHai District , FoShan City , GuangDong Province , China.

Postcode: 528223

ZONESUNPRO.COM is the official website of the ZONESUN brand. To protect your rights, please verify the website address before placing an order to avoid visiting counterfeit or unauthorized websites.

Trust & Guarantee

Trust & Guarantee

Payment & Delivery Assurance

1. Secure Payment

1. Secure Payment

We accept payments via PayPal and major credit cards through official third-party payment platforms. Buyer protection applies in accordance with the policies of the respective payment service providers.

2. Pre-Shipment Verification

Before shipment, a real machine operation and testing video will be provided to demonstrate the actual working condition and key performance of the equipment.

3. Post-Delivery Support

After delivery, installation and commissioning guidance videos will be provided to support proper setup and operation. Technical assistance is available when required.

4. Clear Commitment

If the delivered machine does not meet the agreed technical specifications or materially differs from what was demonstrated in the pre-shipment video, appropriate solutions will be provided based on the specific situation, including technical adjustment or other reasonable handling measures.

About ZONESUN

We are Zonesun, dedicated to building long-term partnerships based on transparency, verifiability, and accountability. We specialize in filling machines, capping machines, labeling machines, and complete automated production line solutions, along with a full range of supporting packaging equipment. For more information, please visit our official website: www.zonesunpro.com

Official Website: https://www.zonesunpro.com

Customer Service Email: info@zonesunpro.com (Kevin Peng)

Whatsapp/Phone/Tell: +86 189 2864 2633

Company Address: No. 8, Lane 1, East Dianbian Road, Nanyue Village, Shangan, Jinsha Town, Nanhai District, Foshan, Guangdong, China

Description

ZONESUN ZS-FAL180G9 is a fully automatic packaging line designed for small and special-shaped bottles, suitable for products such as biological extracts, eye drops and solder flux. The line integrates bottle entry, precision liquid filling, inner plug pressing, outer cap tightening and shrink sleeve labeling to achieve a seamless workflow.

Filling Capping Machine Parameter

- Machine Model: ZS-AFC13A

- Machine Voltage: 110/220V 50-60HZ 8KW

- Filling Pump: Peristaltic Pump

- Recommend Filling Range: 45 ml (Customizable)

- Working Speed: 60 BPM (based on material and volume)

- Filling Accuracy: ±2 ml (based on material and volume)

- Suitable Bottle Size: 52*24*94 mm (Customizable)

- Suitable Cap Size: φ18.6*25.7 mm (Customizable)

- Machine Size: 2318.06*1975*1558 mm

- Machine Weight: About 1608 kg

Sleeve Label Machine Parameter

- Machine model: ZS-STB150

- Bottle diameter range: φ28 mm-φ125 mm (can be customized)

- Bottle height: 30 ~ 280 mm (can be customized)

- Label length: 30~250 mm (can be customized)

- Label thickness: 0.03 mm ~ 0.13 mm (PVC, PET, OPS, materials are all available)

- Sleeve standard error: +1.5 mm

- Paper tube inner diameter: 5"~10" (can be adjusted)

- Machine speed: 150 bottles/min (based on label length)

- Voltage: 220V Single Phase

- Power: 15KW

- Conveyor belt: standard 2M

- Machine size: About 2950*1030*1870 mm(L*W*H)

- Machine weight: About 464 kg

Shrinking Machine Parameter

- Tunnel length: About 1800 mm

- Tunnel width: About 395 mm

- Tunnel height: About 360 mm

- Suitable bottle diameter: ≤80 mm

- Conveyor height: About 900 mm

- Machine size: About 3050*480*1330 mm(L*W*H)

- Machine weight: About 86 kg

- Package size: About 1905*610*1720 mm

- Package weight: About 143 kg

CONTROL PANEL

CONTROL PANEL

CUSTOMIZABLE STARWHEEL

CUSTOMIZABLE STARWHEEL

FULL-BODY SLEEVE

FULL-BODY SLEEVE

STEAM SHRINK TUNNEL

Uniform shrinkage, adapts to round, square, flat, and irregular bottles with even heat distribution.

The ZS-FAL180G9 is our standard automatic eye drop and small bottle filling, capping, and shrink sleeve labeling production line, engineered for stable, continuous operation on industrial packaging lines.

This system integrates cam-driven mechanisms for filling, inner plug pressing, outer capping, and shrink sleeve labeling in one seamless workflow.

The ZS-FAL180G9 line applies a cam-system structure to coordinate rotation and translational motion, ensuring precise liquid filling, secure capping, and reliable shrink sleeve application across varied container shapes and production demands.

Its modular cam-system structure allows high stability at medium production speeds (~40–60 bottles per minute), making it suitable for eye drop lines, biological liquid packaging, and similar small-bottle applications.

This fully automatic production line is widely used in:

- Pharmaceutical & medical (eye drops, vials, ampoules)

- Cosmetics & personal care (essences, serums)

- Specialty liquids (biological extracts, solder flux)

For more specialized configurations, ZONESUN also offers variants and custom OEM solutions based on the ZS-FAL series platform.

As an experienced packaging machinery manufacturer, ZONESUN controls the full production process from design to factory assembly and quality testing.

Every ZS-FAL180G9 unit undergoes rigorous calibration and inspection to ensure long-term stability, precision, and compatibility with continuous production lines.

Share