ZONESUN ZS-GTRP2 Semi-automatic 2 Nozzles Rotor Pump Paste Filling Machine

ZONESUN ZS-GTRP2 Semi-automatic 2 Nozzles Rotor Pump Paste Filling Machine

Couldn't load pickup availability

Pre-sale Support

Pre-sale Support

Chinese Company: Guangdong Shanghang Technology Co., Ltd.

Headquarters Address: No.8,Lane1 East Dianbian Road,Nanyue,Shang An, Jinsha, Danzao Town, NanHai District , FoShan City , GuangDong Province , China.

Postcode: 528223

ZONESUNPRO.COM is the official website of the ZONESUN brand. To protect your rights, please verify the website address before placing an order to avoid visiting counterfeit or unauthorized websites.

Trust & Guarantee

Trust & Guarantee

Payment & Delivery Assurance

1. Secure Payment

1. Secure Payment

We accept payments via PayPal and major credit cards through official third-party payment platforms. Buyer protection applies in accordance with the policies of the respective payment service providers.

2. Pre-Shipment Verification

Before shipment, a real machine operation and testing video will be provided to demonstrate the actual working condition and key performance of the equipment.

3. Post-Delivery Support

After delivery, installation and commissioning guidance videos will be provided to support proper setup and operation. Technical assistance is available when required.

4. Clear Commitment

If the delivered machine does not meet the agreed technical specifications or materially differs from what was demonstrated in the pre-shipment video, appropriate solutions will be provided based on the specific situation, including technical adjustment or other reasonable handling measures.

About ZONESUN

We are Zonesun, dedicated to building long-term partnerships based on transparency, verifiability, and accountability. We specialize in filling machines, capping machines, labeling machines, and complete automated production line solutions, along with a full range of supporting packaging equipment. For more information, please visit our official website: www.zonesunpro.com

Official Website: https://www.zonesunpro.com

Customer Service Email: info@zonesunpro.com (Kevin Peng)

Whatsapp/Phone/Tell: +86 189 2864 2633

Company Address: No. 8, Lane 1, East Dianbian Road, Nanyue Village, Shangan, Jinsha Town, Nanhai District, Foshan, Guangdong, China

DESCRIPTION

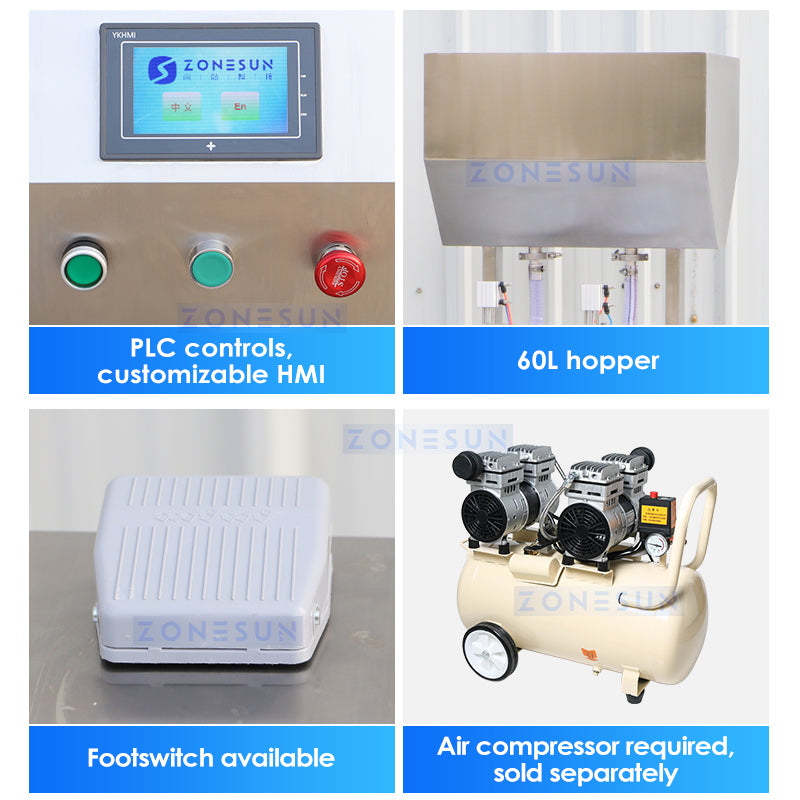

The ZONESUN ZS‑GTRP2 is a semi‑automatic 2‑nozzle rotor pump paste filling machine, engineered for efficient, consistent filling of high‑viscosity pastes, creams, sauces, gels and similar products. It’s perfect for cosmetic creams, food pastes, chemical gels, and other viscous liquids — offering reliability, ease of use, and stable output.

Key Features:

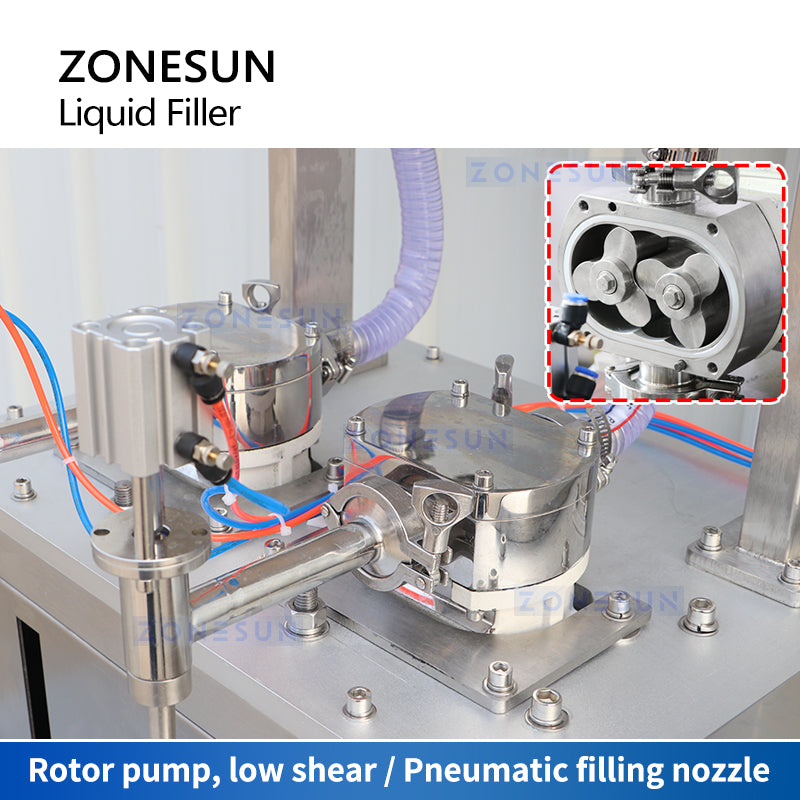

- Rotor pump paste filling system — ensures smooth, precise filling of pastes, creams, gels and sauces, even at high viscosity.

- Dual‑nozzle semi‑automatic operation — doubles efficiency by filling two containers at once, balancing speed and control.

- Adjustable filling volume — supports different container sizes and fill volumes, adding flexibility for various production needs.

- Durable industrial‑grade build — robust structure suited for long‑term, continuous operation in factories or production lines.

- Easy to operate and clean — designed for quick setup, operation and maintenance, minimizing downtime and labor.

Applications:

Ideal for filling cosmetics (creams, lotions), personal care products, food pastes (sauces, condiments), chemical gels, and other viscous liquids in small to medium‑scale production lines.

PARAMETER

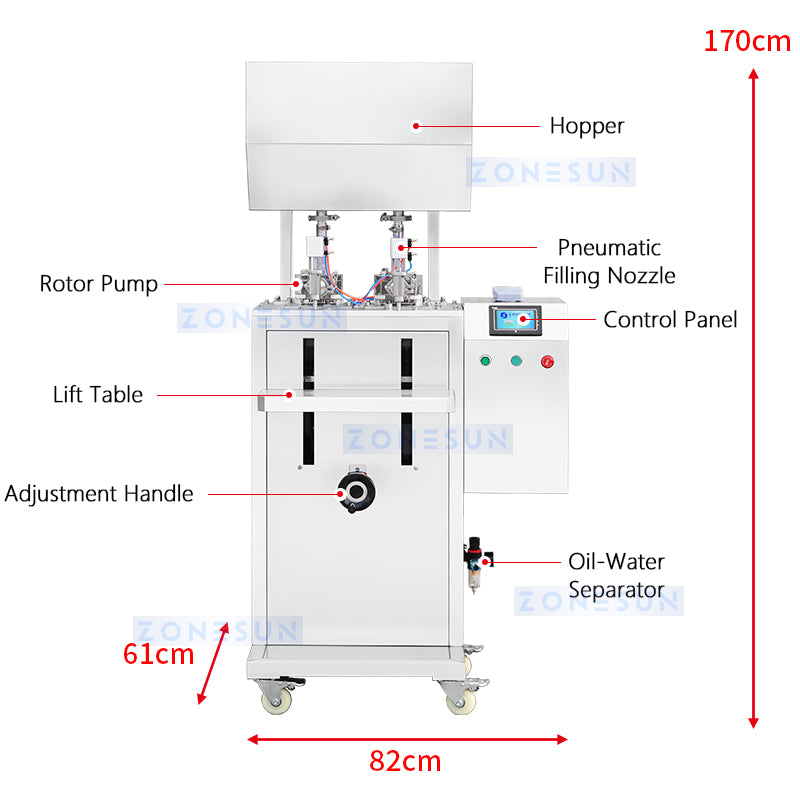

- Machine Model:ZS-GTRP2

- Voltage:110/220V, 50-60HZ, 2kW

- Filling Pump:Rotor pump*2

- Filling Drive:Servo motor*2, 3000rpm

- Recommend Filling Volume:5-5000ml

- Filling Accuracy:≤ ±1%

- Filling Nozzle Size:Φ8mm

- Hopper Size:600*360*400mm(LWH) / 60L

- Working Speed:About 30 bottles/min (1L)

- Machine Size:About 820*620*1700mm(LWH)

- Machine Weight:About 128kg

If you are producing viscous products — such as creams, sauces, gels or pastes — and need a reliable, semi‑automatic filling solution that balances efficiency and precision, the ZS‑GTRP2 offers a robust and flexible choice. It improves productivity, maintains consistent fill quality, and reduces labor compared to manual methods.

Share