ZONESUN ZS-MPCL1 Automatic Magnetic Pump Liquid Filling Line

ZONESUN ZS-MPCL1 Automatic Magnetic Pump Liquid Filling Line

Couldn't load pickup availability

Pre-sale Support

Pre-sale Support

Chinese Company: Guangdong Shanghang Technology Co., Ltd.

Headquarters Address: No.8,Lane1 East Dianbian Road,Nanyue,Shang An, Jinsha, Danzao Town, NanHai District , FoShan City , GuangDong Province , China.

Postcode: 528223

ZONESUNPRO.COM is the official website of the ZONESUN brand. To protect your rights, please verify the website address before placing an order to avoid visiting counterfeit or unauthorized websites.

Trust & Guarantee

Trust & Guarantee

Payment & Delivery Assurance

1. Secure Payment

1. Secure Payment

We accept payments via PayPal and major credit cards through official third-party payment platforms. Buyer protection applies in accordance with the policies of the respective payment service providers.

2. Pre-Shipment Verification

Before shipment, a real machine operation and testing video will be provided to demonstrate the actual working condition and key performance of the equipment.

3. Post-Delivery Support

After delivery, installation and commissioning guidance videos will be provided to support proper setup and operation. Technical assistance is available when required.

4. Clear Commitment

If the delivered machine does not meet the agreed technical specifications or materially differs from what was demonstrated in the pre-shipment video, appropriate solutions will be provided based on the specific situation, including technical adjustment or other reasonable handling measures.

About ZONESUN

We are Zonesun, dedicated to building long-term partnerships based on transparency, verifiability, and accountability. We specialize in filling machines, capping machines, labeling machines, and complete automated production line solutions, along with a full range of supporting packaging equipment. For more information, please visit our official website: www.zonesunpro.com

Official Website: https://www.zonesunpro.com

Customer Service Email: info@zonesunpro.com (Kevin Peng)

Whatsapp/Phone/Tell: +86 189 2864 2633

Company Address: No. 8, Lane 1, East Dianbian Road, Nanyue Village, Shangan, Jinsha Town, Nanhai District, Foshan, Guangdong, China

DESCRIPTION

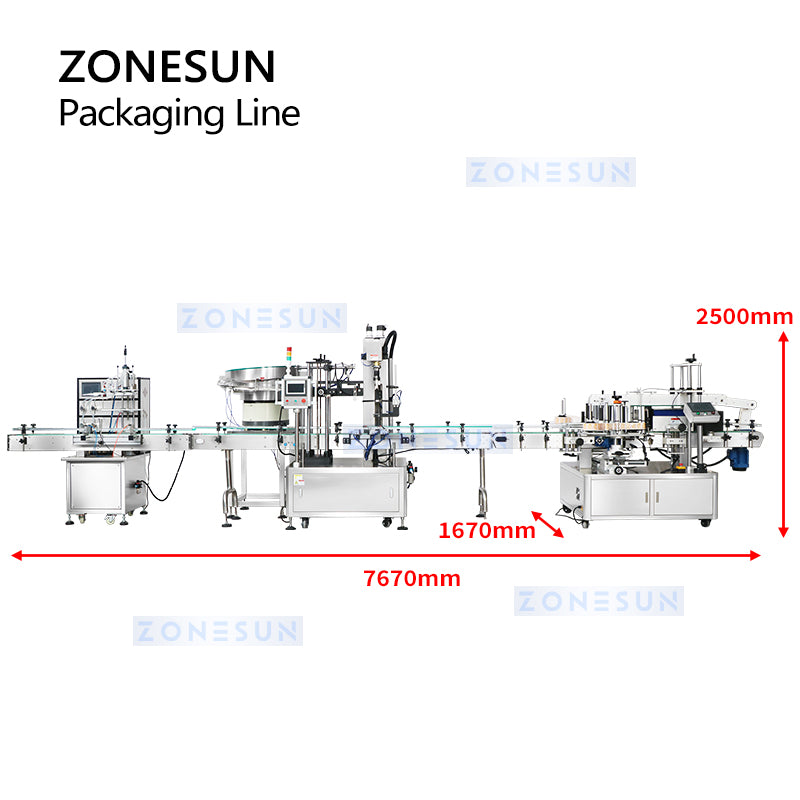

The ZONESUN ZS-MPCL1 is an integrated automatic packaging line designed for precise liquid filling, bottle capping and labeling in a single streamlined workflow. Equipped with high-accuracy magnetic pump technology, this system offers excellent chemical resistance, stable performance and consistent output for daily chemical, cosmetic and household product manufacturing.

|

Machine model |

ZS-VTMP80C |

||

|

Container size |

φ20-160mm H30-300mm |

||

|

Max flow rate |

6000ml/min |

7500ml/min |

12000ml/min |

|

Material of pump |

316stainless steel |

316stainless steel |

316stainless steel |

|

Filling accuracy |

≤±1% (based on water) |

||

|

Filling speed |

20-50pcs/min |

25-60pcs/min |

40-65pcs/min |

|

Power supply |

220V-50Hz/110V-60Hz |

||

|

The whole machine power |

2000W |

||

|

Size of air compressor connector |

OD 8mm |

||

|

Packing weight |

About 150kg |

||

|

Packing size |

About 2000*820*1580mm |

||

|

Machine model |

ZS-XG445 |

|

Voltage |

110/220V |

|

Power |

900W |

|

Capacity |

5-25 bottles/min (based on bottle and cap size) |

|

Material |

304 SUS |

|

Air pressure |

0.6-0.8Mpa |

|

Suitable bottles |

Customize according to the sample |

|

Cap feeding way |

Pneumatic fetch |

|

Capping way |

Servo drive screw capping |

|

Machine size |

About 2900*950*2000mm |

|

Packaging size |

About 3020*905*2140mm(machine) About 1870*1220*840mm (Vibratory bowl sorter) |

|

Packaging weight |

About 600kg(machine)/316kg (Vibratory bowl sorter) |

|

Machine Model |

ZS-TB300A |

ZS-TB300B |

|

Labeling capacity(pcs/min) |

60-350PCS /min(depends on bottle size) |

|

|

Labeling material thickness |

20-120mm |

|

|

Labeling material height |

30-350mm |

|

|

Label size(mm) |

(L)25- 300mm (H)15-200mm |

|

|

Round Bottle |

Single Side |

Single & Double Side |

|

Flat Bottle |

Double Side |

|

|

Roll inside(mm) |

Φ76mm |

|

|

Roll outside diameter(mm) |

Φ350mm |

|

|

Machine size (mm) |

About 2120*940*1500mm |

|

|

Power supply |

AC220V 50Hz/60Hz 1500W |

|

|

Packing Size |

About 2850*1300*1900mm |

|

|

Net weight/Gross weight |

About 450kg/650kg |

|

Overview of the ZS-MPCL1 Automatic Filling Line

(H2)

This fully automatic production line is designed to handle trigger bottles, spray bottles and other plastic or glass containers. It combines magnetic pump filling, automatic cap feeding, capping and labeling functions, ensuring fast, accurate and contamination-free liquid packaging for medium- and large-scale production.

The system is suitable for water-thin to low-viscosity liquids, making it widely used in cosmetics, cleaning chemicals, disinfectants, serums, toners, essential oils and household products.

Key Features

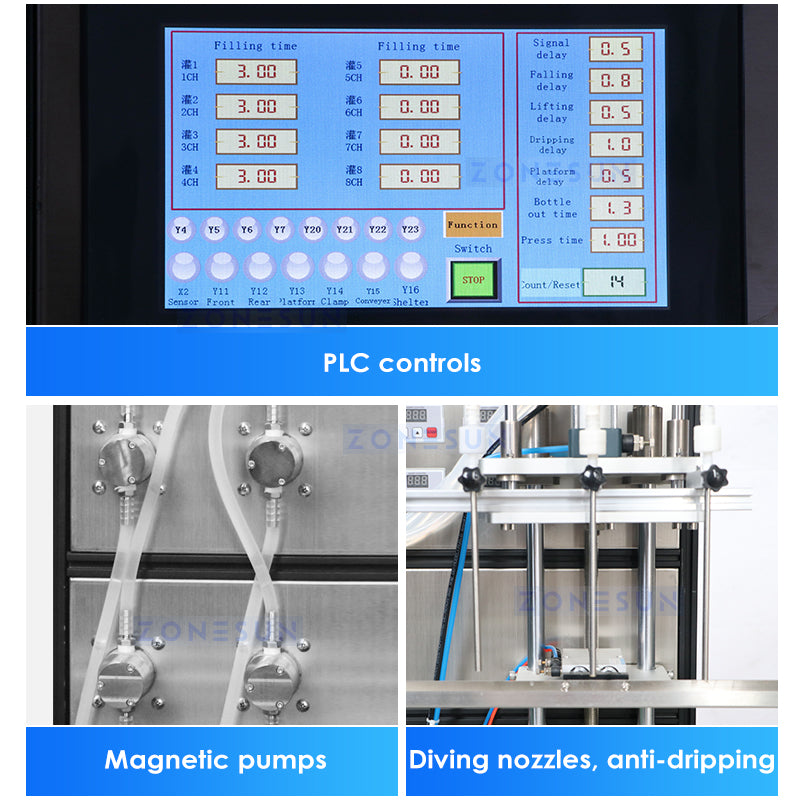

High-Precision Magnetic Pump Filling System

- Utilizes corrosion-resistant magnetic pumps for stable, repeatable accuracy

- Supports multi-head filling for higher productivity

- Suitable for liquids without particles or low-viscosity formulas

- Easy to adjust filling volume, speed and timing via touch screen

Automatic Trigger Bottle Capping System

- Automatic cap sorter and feeding mechanism

- Strong and consistent tightening torque

- Compatible with trigger sprayers, pump heads and screw caps

- Reduces labor and increases efficiency

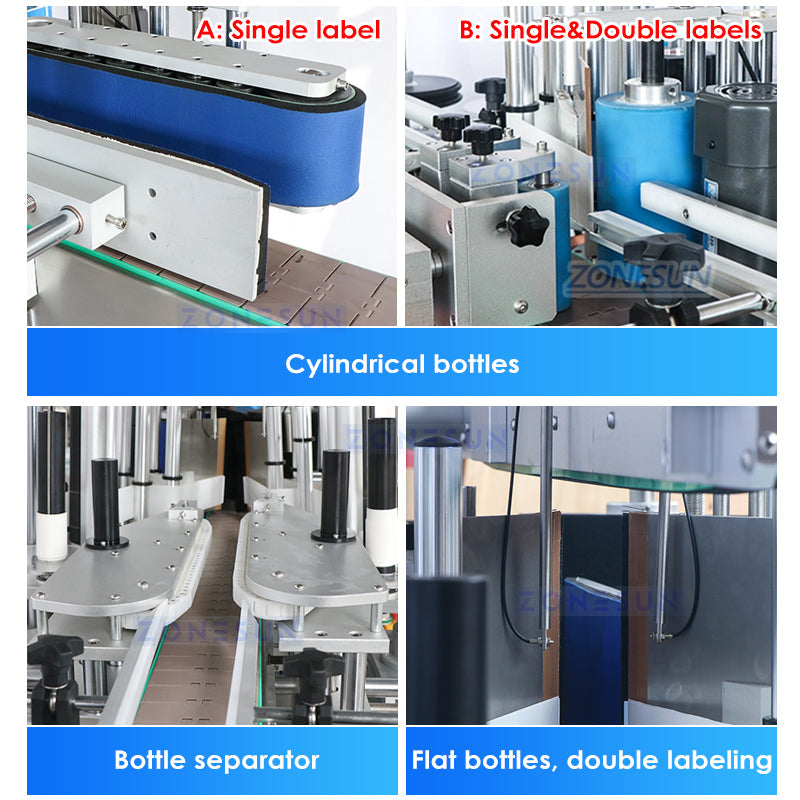

Fast and Accurate Labeling Module

- Supports round, square and flat bottles

- High-speed label application with precise alignment

- Adjustable label height and positioning

- Optional date coding and batch printing

Applications

The ZS-MPCL1 is ideal for manufacturing businesses in:

- Cosmetic production (toners, serums, make-up removers)

- Daily chemical industry (detergents, glass cleaners, sanitizers)

- Household products (room sprays, cleaners, essential oils)

- Chemical solutions (reagents, disinfectants, solvents)

Designed for flexible bottle formats, it provides maximum compatibility for different product lines.

Why Choose the ZS-MPCL1?

- Fully automated workflow reduces labor costs

- High stability and low maintenance due to magnetic pump structure

- Flexible customization options for filling heads, conveyors and labeling modules

- Durable stainless steel construction, compliant with hygiene requirements

- Touch screen interface with easy operation and precise control

- Suitable for small to large batch production

Frequently Asked Questions (FAQ)

1. What types of liquids can the ZS-MPCL1 fill?

It is suitable for water-like and low-viscosity liquids without solid particles, such as toner, disinfectant, cleaning solutions, essential oils and similar products.

2. Can the machine work with different bottle materials?

Yes. It supports most plastic and glass bottles, including round, square and irregular containers.

3. Is the filling volume adjustable?

Yes. The touch screen allows precise adjustment of filling volume, speed and interval.

4. Does it support custom labeling requirements?

The labeling module is customizable for single-side, double-side or wrap-around labeling, with options for printing date codes.

5. Can this production line be customized?

Yes. ZONESUN can customize filling heads, conveyor length, capping systems, labeling configurations and other modules based on your production needs.

Share